002. MATERIALITY

felt

Written by Frances Vigna

New parents inherently want to protect their children. The desire to keep a baby warm and dry is strong, and it seems that there’s no better material for safeguarding little ones than wool. (Think thick blankets and cozy mittens.) Wool felt, in particular, ticks off all the boxes of a highly practical material for child-rearing. Its softness, flexibility, and durability make it perfect for tiny hands to manipulate, and because it is naturally nontoxic and eco-friendly, it can be safely applied to any space for children, from nurseries to elementary schools. However, while wool felt has been crafted for thousands of years, designers have only fairly recently begun exploiting the material for daily use by children.

Wool felt is considered by most historians to be the oldest textile, with handmade versions appearing in cultures across Southeast Asia and the Middle East for more than eight millennia. Some textile historians theorize that wool felting arose alongside the domestication of sheep, from between 9000 and 7000 BCE. Sheep’s wool is most often used in the production of felt, because its particular crimping pattern is especially effective at creating a strong bond between fibers, but goat hair (mohair) and rabbit hair (angora) are also used.

Large-scale wool-felt production is achieved using a wet-process method, which involves compressing layers of animal fibers and agitating them in hot water, causing the strands of hair to entangle. The matted material then undergoes a shrinkage process called fulling, which creates a dense, strong fabric. Plant material and synthetics can be felted as well, through a process that utilizes notched needles to interlock the fibers much the same way that agitation and pressure entangles animal hairs. In industrial settings, synthetic materials such as rayon and viscose are oftentimes combined with natural wool to create a more affordable product, but one-hundred-percent-wool felt is considered the highest quality for its ability to withstand wear.

The most forward-thinking solutions often come from the oldest sources, and this ancient material has proved a good fit for child design. “Parents are rightly concerned about the materials that surround their children and the impact of those materials on their children’s health and on the health of the environment,” says Susan Brown, associate curator in the textiles department at the Cooper Hewitt, Smithsonian Design Museum, and lead curator of the 2009 exhibition Fashioning Felt. “Those concerns grow more urgent every day, as we see the effects of global climate change play out.” Unlike the molded plastics and composite laminate materials typically used for modern children’s furnishings, she explains, pure wool felt, because it is made from only wool and water, contains no volatile organic compounds (VOCs) or other potentially harmful chemicals. And with recent advances in manufacturing technology, the production of wool felt could be one solution to a growing desire for ecologically sustainable design for children.

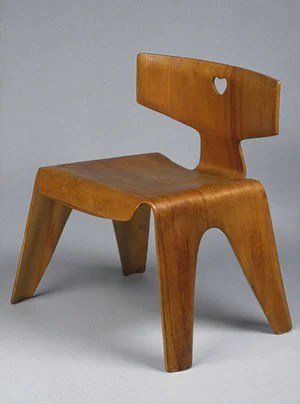

Unlike woven wool fabric, felt is tough relative to its thickness and its edges do not need to be finished to stop the material from fraying; these characteristics make it ideal for use in child design. Additionally, the tactile qualities of felt are valued by parents of young children, who look to the material to keep little ones occupied. During the Second World War, British designer Lois Allen, who had been creating felt gaskets for sealing tank components, noticed how her children enjoyed playing with the leftover textile scraps from the manufacturing process. Allen designed a flocked backing board with felt pieces for creative play, and patented it in 1950 as Fuzzy-Felt. “Quiet books” are popular as a relatively simple toy that can also serve as an effective teaching tool. Crafted entirely of felt, these books have soft pages with movable parts, so that children can rearrange characters and events in the story and control the narrative. The material is also favored among parents of children with neurological and developmental conditions for its tactility. Sensory toys made of wool felt, such as simple finger puppets, engage children in multiple ways, and can aid in the development of communication, sequencing, and fine motor skills.

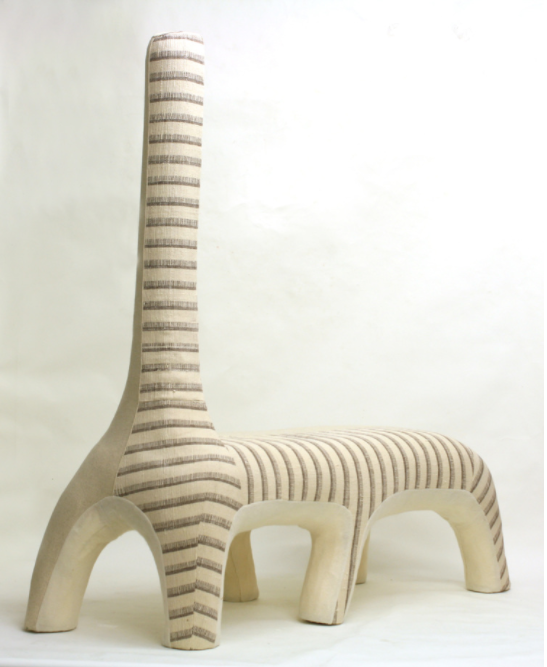

Because of its versatility, the material also appeals to architects and interior designers. “Felt can be made very dense, so it can serve as a cushion with integrated color and surface, eliminating the need for toxic foams and reducing the overall manufacturing footprint (over a traditional foam cushion with woven upholstery fabric and zipper),” says Susan Brown. According to Helene Renard, an associate professor in the school of architecture and design at Virginia Tech, wool felt is desirable for its durability, its sustainability, and its sound-dampening, fire-resistance, and insulating properties. While these qualities have traditionally been exploited in the automotive and music industries, Renard explains in “Felt and the Emerging Interior,” which appears in the book Textile Technology and Design: From Interior Space to Outer Space (Bloomsbury, 2016), designers are reimagining the role wool felt can play in interiors. Functioning as everything from wall coverings to furniture-construction material, felt is now applied to almost every feature of the contemporary domestic space.

New technology has allowed textile manufacturers the ability to manipulate the ancient material in inventive and sustainable ways. Earlier this year, at the International Interiors Show in Cologne, design students from Angewandte Kunst Schneeberg devised multiuse furniture in Lanisor, a felt-reinforced composite material that can be produced with water-repellent and antibacterial properties. Among the furniture was a gray-felt bassinet featuring a wooden-rod base that can be rearranged into a toddler-size seat swing, a design that could prove valuable in meeting the needs of a growing child.

In 2012, the iconic furniture company Knoll purchased FilzFelt, a German industrial-wool manufacturer whose portfolio includes wall coverings in a Boston private elementary school. According to Brown, “Felt is a boon to learning spaces because of its excellent acoustic properties.” A one-inch-thick piece of industrial wool felt has a greater noise reduction coefficient than carpet, she says. The company’s whimsically shaped CNC-cut Wool Design Felt panels are biodegradable and contain no formaldehyde, VOCs, or chemical irritants, making them perfect for children’s environments.

“From an ecological standpoint, all materials have pros and cons,” Susan Brown says. And the production of wool for felt is resource-intensive, from raising the sheep to cleaning the fleece to washing the cloth. But felt can also be fabricated from recycled wool, significantly lowering production costs and environmental impact. If manufacturers are careful, the production of wool-felt designs for children may be the safest and greenest choice, and ultimately, the most viable option for families in the future.