002. MATERIALITY

TUBULAR STEEL

Written by Frances Vigna

While most people wouldn’t look at a material found in industrial settings and construction sites and immediately see its applicability to child design, a few forward-looking designers at the beginning of the last century understood the possibility of tubular steel in the life of a child. In comparison with earlier metal furniture, which was usually made of heavy solid cast iron that corrodes easily, steel designs are more durable and less expensive to produce. And early twentieth-century designers and manufacturers were onto something.

Tubular steel eventually secured its place in the design world, being used in everything from refrigerators to bicycles, but the material had modest beginnings. The metal became widely used in manufacturing in the 1860s, after the introduction of the Bessemer industrial process, which allowed for the mass production of inexpensive steel from crude iron. The now-obsolete process involved removing impurities from molten iron by blowing air through it, leaving behind high-quality mild steel, which quickly became the material of choice for building construction. The earliest steel tubes were made by rolling sheets of metal and welding the edges together. By the turn of the last century, technological improvements allowed for high-volume manufacture of seamless tubes, made by hollowing out solid pieces of steel. As demand for military-grade solid steel rose during the Second World War, manufacturers returned to welding, which was more cost-efficient but produced less stable materials. Today’s welding processes, however, can be used to create hollow tubes that are as strong as those made from solid steel.

Steel is a very malleable material, and Marcel Breuer exploited this characteristic when he designed the model B3 chair (later known as the Wassily chair, as it was a favorite of Kandinsky’s) in the mid-1920s, while teaching at the Bauhaus art school in Dessau. Modeled after an overstuffed club chair, the B3 comprises leather slings attached to a spare tubular stainless-steel frame, inspired by the curved steel handlebars of the bicycle Breuer rode to school daily. A year later, the Hungarian designer would push the material further by rendering a minimal, cantilevered tubular-steel chair that integrated the base, seat, and back into one cohesive form.

Breuer also enthusiastically employed cantilever design in the chairs he developed for children. In 1929, he designed the B33½ and B34½ chairs in tubular steel with blue canvas slings for Thonet. Luke Baker of the Museum of Modern Art’s Architecture and Design department explains why tubular steel is an ideal material for children’s furniture: “It's lightweight, which makes it portable even by a small toddler; it's nonporous, which makes it hygienic and easy to clean; and it's durable and can hold up to years of use and abuse.” The chairs’ durable and lightweight frames make them perfect for a child’s use, and, according to Baker—who, along with Juliet Kinchin, co-curated MoMA’s “How Should We Live? Propositions for the Modern Interior”—their cantilevered design “provides a subtle springy sensation that's fun for bouncing.” Breuer’s furniture pieces, especially with the introduction of the B53 table, which featured tubular-steel legs, gained status as the leading designs for the modern children’s room.

The durability that made steel the preferred material for bicycles in the nineteenth and twentieth centuries also made it a favorite of postwar toy manufacturers, whose designs reflected the role of creative play in child-rearing in the emerging middle class. As the processes for producing tubular steel became quicker and less expensive, toy design became less limited to traditional materials such as wood, which was often carved by hand and could dry out and splinter. An especially inventive twentieth-century toy is the Walkee tricycle, patented in 1938 by the Fageol Motor Company. The tricycle has one wheel in the rear, and two front wheels supported by arching tubular-steel legs that allow a child to scoot the toy across the ground. The tricycle’s designer, William Fageol, believed that tubular steel’s ruggedness made it ideal for children’s toys. And, following the rise of designated outdoor play areas in the late nineteenth century, playground equipment from merry-go-rounds to seesaw handles benefited from the rust resistance of painted tubular steel.

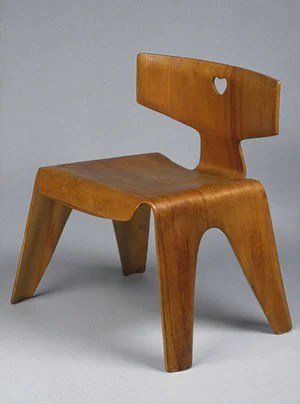

Perhaps the most prevalent trend in child design that incorporates tubular steel is a base that can be reconfigured to suit multiple seat options. A hallmark of midcentury design, developed by Charles and Ray Eames, a metal base with a single-sheet injection-molded plastic seat worked perfectly in elementary schools. As Luke Baker points out, combining numerous seats and multiple leg configurations results in chairs that are stackable and easy to store in classrooms with limited space. Later pieces such as the Series E polyprop chair, designed by Robin Day for Hille in 1963, would become ubiquitous in British schools.

Designs that serve a variety of purposes by, for instance, incorporating multiple bases and inviting reconfiguration were a welcome innovation for many midcentury families. According to Baker, a multipurpose design “makes efficient use of space in the home, especially in the smaller modern apartments that began to crop up in urban areas in the early twentieth century.” Tubular steel was often used for multiuse child design, as its light weight makes it portable even for young children. “Some pieces of adaptable furniture also grow with the child and allow different functions to match their users’ growing mobility, autonomy, and size,” says Baker. “These pieces are particularly well suited for families with multiple children, who might need to adapt the same object for use by children of different ages, or as hand-me-downs.” Additionally, as women entered the workforce, “designs for children that saved time and effort made it easier for working mothers to juggle the numerous demands of modern life.”

Today’s designers of children’s furniture continue the tradition of employing tubular steel in low-maintenance pieces that stand up to wear and tear. Since its introduction in the 1960s, powder coating in bright, fun colors has often been utilized instead of chrome, which is less scratch- and rust-resistant, and paint, which can be picked off and ingested. And combined with new durable materials such as fade- and water-resistant fabrics, tubular steel appears in pieces for children ranging from chairs, tables, and desks to bed frames, dressers, and outdoor furniture.

It’s not surprising that steel, a material that can withstand the heavy weight of a building or the corrosion of wind and rain, works so well in the rough-and-tumble world of children. When tubular steel is plated in chrome or coated in an industrial powder, the result allows a child to drag a chair across the floor, push a tricycle over on the pavement, or use a desk as a fort without causing much damage—at least to the chair, tricycle, or desk! For these reasons, even as other new materials have demonstrated their own potential since the middle of the last century, tubular steel has maintained its role in the daily lives of children.