002. MATERIALITY

fiberglass

Written by Frances Vigna

The injection-molded fiberglass shell-chair designed by Charles and Ray Eames is considered an icon of postwar modern design. For years, the chair served as a model for multiuse furniture, and could be seen in settings as varied as airports, hospital waiting rooms, elementary school classrooms, and nurseries. Its simple, clean aesthetic set the standard for urban interiors after World War II. But traditional fiberglass is not an ecologically sustainable material, and designers and manufacturing companies, including Herman Miller, have for years tried to solve the problem of producing accessible furniture that is nontoxic to both their consumers and their factory workers. And recently, designers have begun pairing new materials in traditional forms with advanced production techniques to create partly and fully recyclable fiberglass furniture.

In partnership with the University of California–Los Angeles department of engineering, the Eameses devised a stamped-steel seat that could be configured with multiple base options for a 1948 competition at the Museum of Modern Art. The International Competition for Low-Cost Furniture Design sought revolutionary manufacturing processes and ingenious models to meet the needs of growing families after the Second World War. The competition guidelines required that designs be adaptable for a variety of uses; the chair won second prize. The molded-steel design, however, was expensive to manufacture, making the chair too costly for young parents. Accessibility being one of the Eameses’ key design tenets, Charles and Ray collaborated with UCLA, Herman Miller Inc., and plastics manufacturer Zenith to refine their model. The end result was a molded polyester seat reinforced with glass fibers—more commonly known as fiberglass—created for the newly formed Plastic Shell Group in 1950.

While glass fibers had been used in industrial settings previously, it wasn’t until the 1930s that a researcher at glass company Owens-Illinois developed a method for mass-producing it using jets of compressed air. In 1936, Corning Glass Works patented the material as “fibreglas” for use as insulation. That same year, the DuPont company created a strong, durable composite material of glass fibers and resin, which manufacturers quickly realized could be used as a low-cost, easy-to-produce building material.

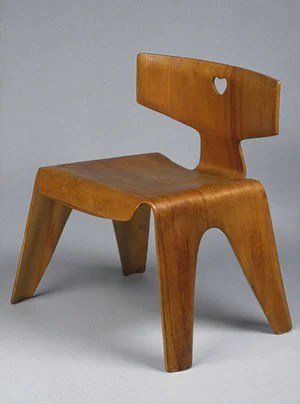

The original manufacturing process of the fiberglass shell-seat was similar to the production of felt hats. Glass fibers were fed into a machine that used air to deposit them onto a screen. A dry or liquid resin was then mixed with the fibers to bind them and allow them to be formed into the desired shape. Once the preform was placed on the mold, a liquid polyester resin was poured in and the second half of the mold was pressed into the first, dispersing the resin evenly throughout the mold for curing. The process left the seat with a distinctive textured surface, and when the chair went on sale that year it was available in three colors: greige, elephant gray, and parchment. The bases ranged from four wooden dowels to a wire Eiffel Tower–inspired design to a rocker for nursing mothers (female employees at Herman Miller were gifted these rocking chairs when they gave birth).

Glass-reinforced thermosetting plastics were originally used in industrial settings, for such things as car and boat bodies and piping, and they proved equally utilitarian in children’s furniture design. According to design historians Peter and Charlotte Fiell, fiberglass is weather-resistant and relatively lightweight for its overall strength and load-bearing capabilities. The Eameses’ uniform injection-molded seat design had the additional advantage of being seamless, making it more hygienic, as dirt would not stick to its surface. Also, fiberglass's color is impregnated into the plastic when resin is poured into the mold, so there’s no paint for children to pick off and ingest.

Injection-molded fiberglass has been used in elementary school settings for decades. The plastic seat with multiple base designs ensures that at a relatively low cost schools can purchase chairs for a variety of uses in the classroom (and replace them if they break). Because the chairs are lightweight, children can easily lift and move them themselves, as well as stack them to save storage space. And they’re easy to clean and require little effort to maintain. With its great strength and resilience, fiberglass is also a perfect material for outdoor recreational equipment, such as playground slides and picnic tables. Its durability allows rough-and-tumble play, and dirt easily washes off of it in the rain. Also, since fiberglass can be injection-molded into any shape, designs for playground equipment are essentially limitless. Fiberglass works especially well for the whimsical shapes and motifs of spring riders—outdoor rockers on large, sturdy springs—from circus animals to motorbikes and cartoon characters.

Today, Brooklyn-based designers Chen Chen and Kai Williams are employing elements of midcentury furniture construction to create new fiberglass chairs for children. Their bucket chair and double-seat chair in fiberglass and steel feature red plastic seats in avant-garde designs. Many thermosetting plastics are brittle, and when they break cannot be repaired as easily as metal or wood. According to Chen, he and Williams chose to work with traditional fiberglass because of its durability and sustainability—it does not degrade as quickly as other plastics, and contaminate the environment. The whole form of the chairs’ design can be disassembled and repaired if any part breaks, and the steel frame is recyclable.

By the late 1980s, the Herman Miller company and Ray Eames were growing increasingly concerned about the sustainability of the material construction and manufacturing process of the shell chair. Because fiberglass is chemically complex and unrecyclable, the company chose to retire the design in 1989. For more than a decade, Herman Miller explored alternative plastics that would be safer for their employees to handle during the chair’s production and would have a smaller ecological footprint. In 2000, the company began offering the design in a recyclable polypropylene. But it wasn’t until nearly fifteen years later that Herman Miller devised a new fiberglass material chemistry and manufacturing process that eliminated volatile organic compounds and other pollutants, ultimately making it safer, more sustainable, and more eco-friendly. According to the company, "the new fiberglass is now formed and processed using a woven, 'dry binder' method instead of the traditional 'wet' process, eliminating wet glue adhesives and instead relying on a heat-activated, dry polyester. This has also eliminated the need for thermal oxidizers and other environmental control equipment in the production process. Combined with a new 'monomer-free' resin, the production process for the new fiberglass chairs is emission-free and creates a safer environment for the workers handling it, as well as a greener, recyclable shell at the end of the chair’s useful life." In 2015, the new fiberglass-shell chair was awarded a GREENGUARD Gold Certification, verifying its safety in environments such as schools and for use by children.

All traditional plastics are problematic materials for designers and manufacturers to produce ethically. Recycling certain plastics is costly and can be as harmful to the environment as throwing them away. And since children outgrow furniture quickly, designs in plastic often end up in landfills. While traditional fiberglass is durable and has a smaller ecological footprint than other thermosetting plastics, it is not recyclable. But with companies such as Herman Miller developing new material chemistry for fiberglass, we should soon see an increase in sustainable design options for plastic children’s furniture.